Conveyor tunnel systems

Success by design

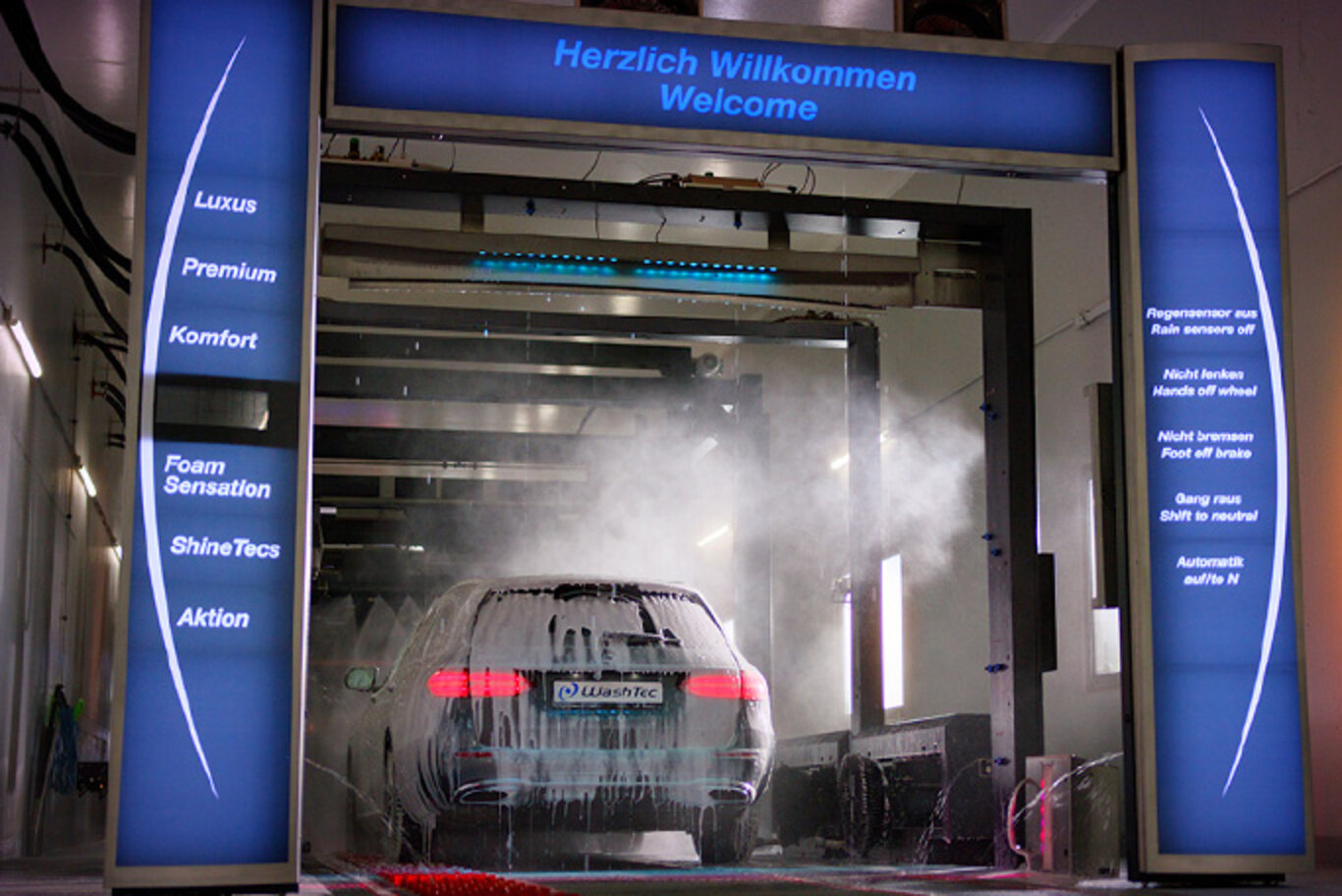

Your WashTec conveyor tunnel system is more than the sum of its parts – it's a precise interplay of technology, chemistry, control and service. WashTec combines all these elements into a high-performance overall system. With modular system options, smart control and reliable service, we provide the ideal basis for an efficient, future-proof washing business.

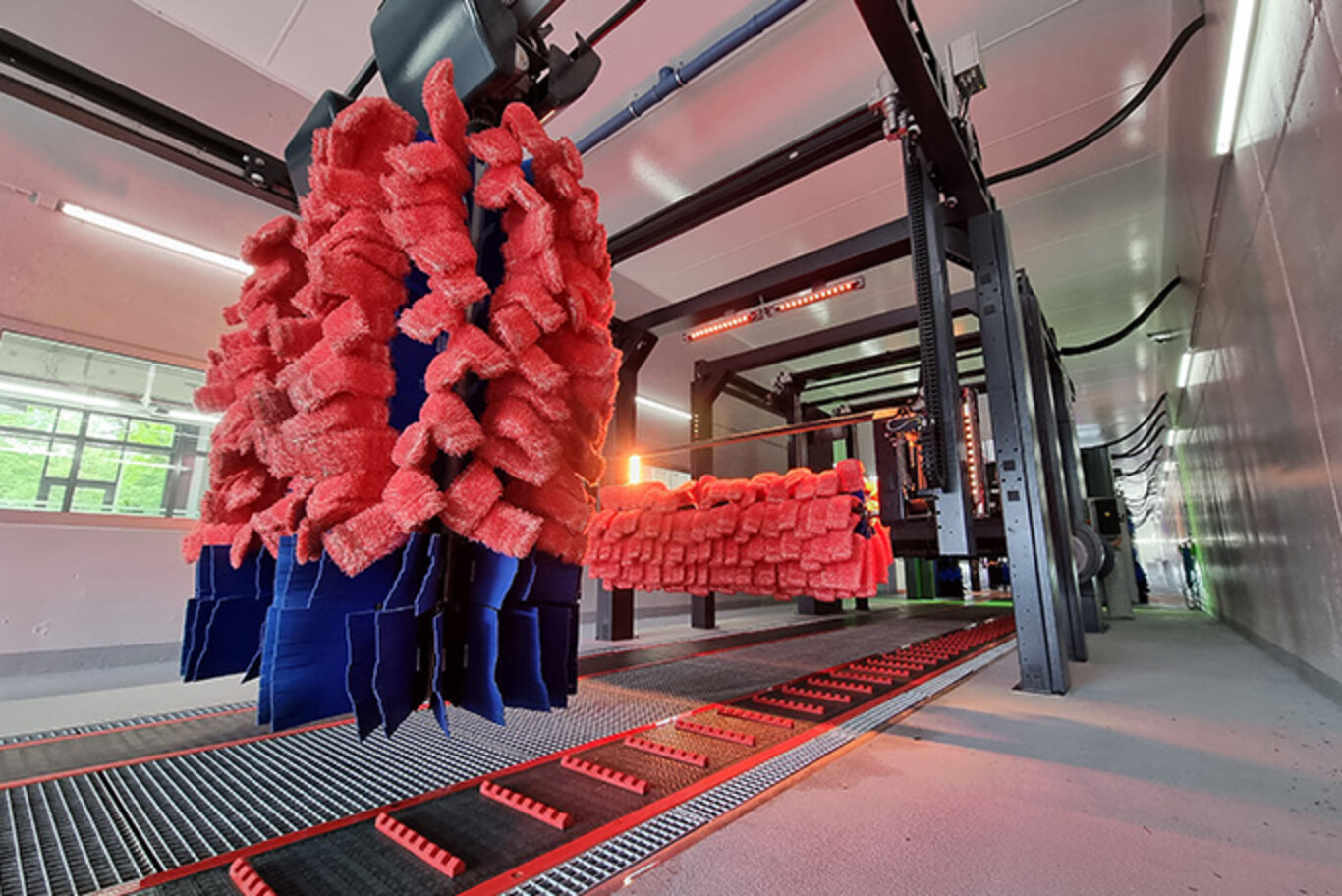

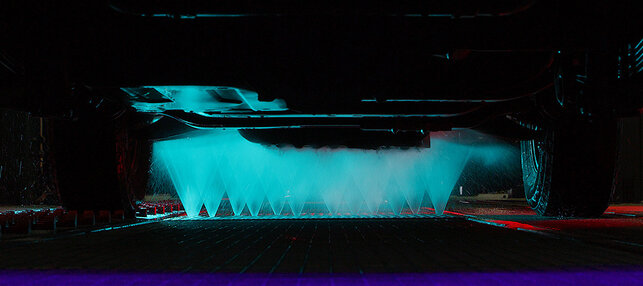

Experience linear technology

In the video, you can discover what makes WashTec conveyor tunnel systems so unique: sophisticated linear technology which guides the wash brushes along the vehicle in a contour-tracking manner and provides special washing quality where it is needed.

Speak with a WashTec expert

More success with integrated solutions

WashTec provides everything that a successful car wash business needs: a highly flexible, modular conveyor tunnel system, high-quality washing chemicals, accessories and reliable service. The smart control system combines all components into an individually configurable and flexibly expandable overall system – perfectly aligned with your goals.

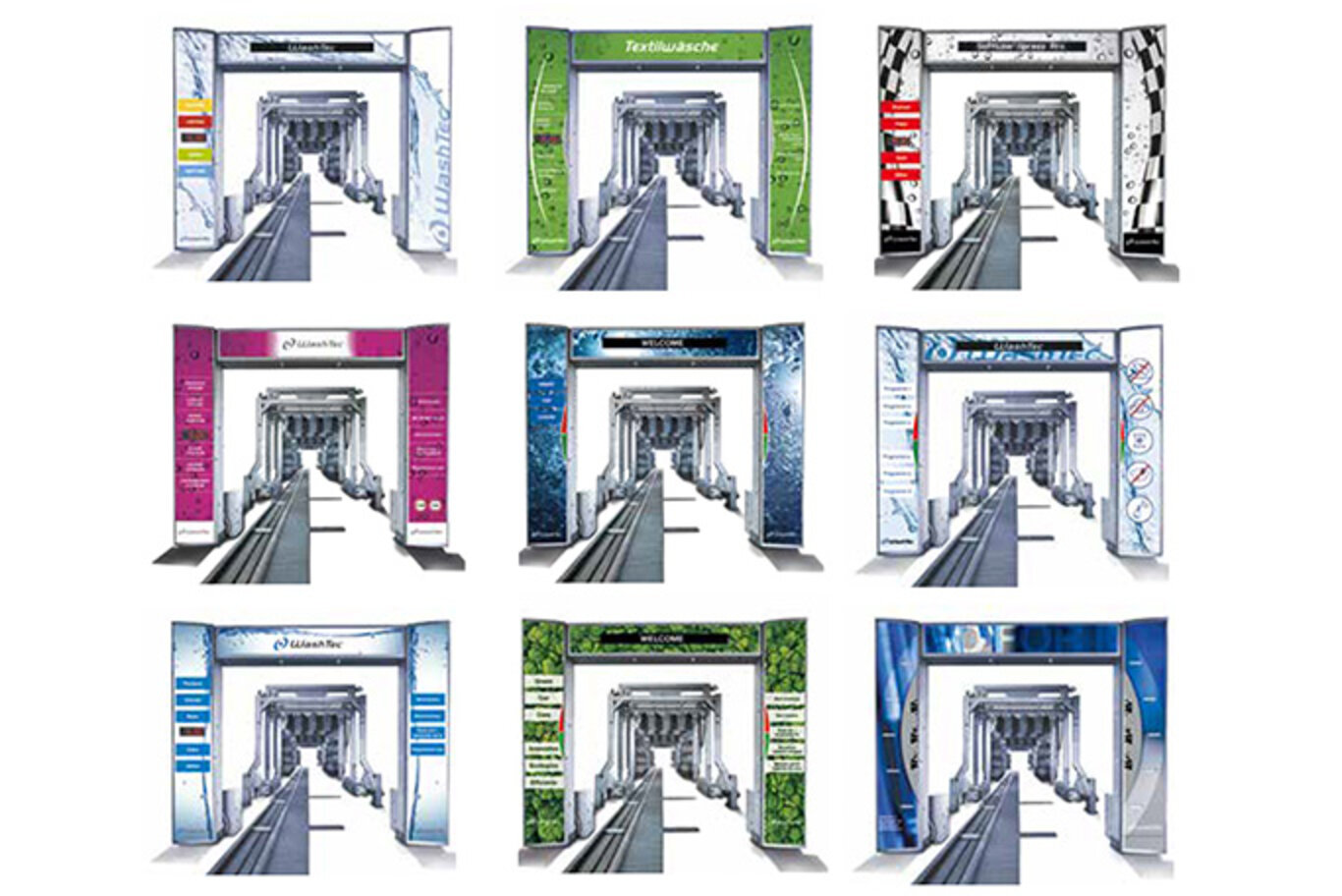

Success in car wash – as individual as your business

Hundreds of successful customers rely on conveyor tunnel systems from WashTec – tailored to their needs, with countless options for equipment and design. Get inspired.

Book your consultation

Rely on professional expertise from the market and innovation leader in vehicle washing, who will support you from the very beginning – practically, individually and without obligation.

Contact